I remember years ago I was involved in a project that involved analysis of critical field failures. Fuel lines were leaking and catching fire. As it turned out, thermal degradation that occurred during the extrusion process had caused cracking in the lines. Post extrusion, the tubing looked fine. After the braided layers were added and end fittings were swaged into place, the finished hoses were shipped. At installation they were bent to fit tortuous pathways. Then the hoses were placed into service, cycled through the heat of summer and the cold of winter. They failed.

Sometimes applications can tolerate some level of thermal or mechanical degradation. Some critical applications cannot.

In our industry we ask a lot of our materials. They are compounded – sometimes more than once. They are extruded, blown, stretched, heated, reheated, assembled and sterilized.

Our extrusion equipment was designed to preserve the mechanical and thermal properties of every material we process. If it is important to your application, please help us understand. We are here to help.

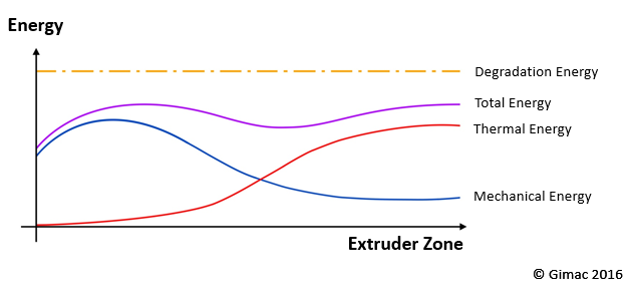

We have uploaded an EMDT article that explores this topic in more depth. For a quick view, take a look at the graphic, below. To read the full article, click here. https://microcathco.com/wp-content/uploads/2016/10/110303NextGenMicroextrusionArticle-1.pdf