Hitting the mark in custom micro-extrusions. The specification isn’t the end. It’s the beginning.

We produce custom micro-extrusions to our customers’ specifications. While the specification provides initial guidance it is often not complete enough to guarantee optimal results. Working with our customers’ engineers and buyers we build our understanding beyond the specifications. We know that it can be possible to hit the specs and miss the mark. Fulfillment of an order marks the start of the next phase of optimization. Follow up and follow through are essential to building the strong foundation needed to support the life of future generations of medical devices.

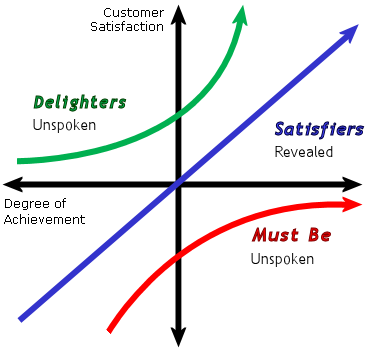

In our office hangs a copy of the Kano Model. The Kano Model characterizes aspects of quality along two axes. Along the X axis is the presence of the desired characteristic. Along the Y axis is the degree of customer satisfaction. This model emphasizes the voice of the customer as critical to quality. It is a visual that captures our aspiration to deliver what will ultimately delight our customer. We are invited to be curious about how our products work for them. How we might best draw from our experience and leverage our technology to deliver our customers products and service that deliver essential value, improve product designs, reduce assembly costs, broaden the capabilities of their products.

Technology, curiosity, intention and determination guided by the voice of our customer, all essential to hitting the mark.

Kano Model